The special program "Test wizard" determines the necessity of the machine calibration

The user can carry out all measurements independently (shaft, gauge arms, imbalance sensors and laser pointer).

Step by step calibration instructions with pictures and detailed descriptions.

/div>

- Main

- -

- Catalog

- -

- Wheel balancing equipment

- -

- Helios

Helios 235-20

• High-precision premium class wheel balancer

• Advanced functionality, modern design, advanced ergonomics

• Suits for alloy wheels balancing

• Equipped with no-touch sonic sensor and electro-mechanical shaft to provide the best performance

• Equipped with laser pointer to improve operating speed

• New design. The operator can stand close to the machine, which simplifies access to the cells (worktable) and to the control panel. Easy access shaft positioning.

• Control shaft rotating by pedal. This ensures easy tightening and quick locking nut removal.

• The modern machine is designed specially for high loaded tire shops, service stations and repair posts.

FEATURES AND FUNCTIONAL COMPOMENT:

Direct3D – accurate direct alloy rim measurement

S-Drive - automatic weight installation wheel, positioning and holding

AutoClamp - clamping assistance by the pedal

AutoALU - automatic weight setting scheme estimation

NoTouch - no button pressing required

RimRunOut - rim geometry troubleshooting

LaserPointer - six-o’clock weight position dot

PowerGuard - power surge protection

Split – aesthetic tape weight installation

Serviced wheel counter

Installed weight counter

Detailed operation report with data export function

Three user profiles

Tire positioning function

Static imbalance minimization

Testing and calibration wizard

Adaptor imbalance compensation

Voice Guide

Ergonomic workplace

Diameter and distance measuring electronic gauge arm

Automatic wheel clamping electromechanical device

Width measuring sonic sensor

High- precision spindle block (40 mm shaft diameter)

Laser pointer

Increased shaft length for wide wheels balancing

Easy access shaft positioning

Space saving wheel cover design

LED balance weight placement highlighting

Electro magnetic brake

• Advanced functionality, modern design, advanced ergonomics

• Suits for alloy wheels balancing

• Equipped with no-touch sonic sensor and electro-mechanical shaft to provide the best performance

• Equipped with laser pointer to improve operating speed

• New design. The operator can stand close to the machine, which simplifies access to the cells (worktable) and to the control panel. Easy access shaft positioning.

• Control shaft rotating by pedal. This ensures easy tightening and quick locking nut removal.

• The modern machine is designed specially for high loaded tire shops, service stations and repair posts.

FEATURES AND FUNCTIONAL COMPOMENT:

Direct3D – accurate direct alloy rim measurement

S-Drive - automatic weight installation wheel, positioning and holding

AutoClamp - clamping assistance by the pedal

AutoALU - automatic weight setting scheme estimation

NoTouch - no button pressing required

RimRunOut - rim geometry troubleshooting

LaserPointer - six-o’clock weight position dot

PowerGuard - power surge protection

Split – aesthetic tape weight installation

Serviced wheel counter

Installed weight counter

Detailed operation report with data export function

Three user profiles

Tire positioning function

Static imbalance minimization

Testing and calibration wizard

Adaptor imbalance compensation

Voice Guide

Ergonomic workplace

Diameter and distance measuring electronic gauge arm

Automatic wheel clamping electromechanical device

Width measuring sonic sensor

High- precision spindle block (40 mm shaft diameter)

Laser pointer

Increased shaft length for wide wheels balancing

Easy access shaft positioning

Space saving wheel cover design

LED balance weight placement highlighting

Electro magnetic brake

Add to comparison

“TESTING AND CALIBRATION WIZARD” FOR CALIBRATION NECESSITY CHECK"

AUTOMATIC DISTANCE AND DIAMETER ENTRY BY THE GAUGE ARM

STELLAR (P) is equipped with the diameter and distance measuring electronic gauge arm which provides high speed operation and eliminates errors

ELECTRO-MECHANICAL SHAFT

Excellent centering regardless of the human factor.

Wheel balancing in one cycle.

Takes care of the operator’s back.

Convenient pedal control.

Does not contain parts subject to rapid wear (nut and threaded shaft).

Wheel balancing in one cycle.

Takes care of the operator’s back.

Convenient pedal control.

Does not contain parts subject to rapid wear (nut and threaded shaft).

HIGH QUALITY OF BALANCING (QUALITY WHEEL CENTERING)

The wheel is automatically pressed against the cup on the electromechanical shaft. There is an accurate wheel centering on the cone.

High- precision spindle assembly provides high quality balancing. Main balancing parts are manufactured with the precision of ±0.007 mm (shaft, threaded jaws, spindle).

40 mm shaft diameter allows the use of accessories from European manufacturers.

High- precision spindle assembly provides high quality balancing. Main balancing parts are manufactured with the precision of ±0.007 mm (shaft, threaded jaws, spindle).

40 mm shaft diameter allows the use of accessories from European manufacturers.

RIM GEOMETRY DISTURBANCE EVALUATION

The set includes the runout measuring roller. It allows to determine the necessity to repair or replace the rim.

THE BEST ERGONOMICS AMONG SIVIK BALANCING MACHINES

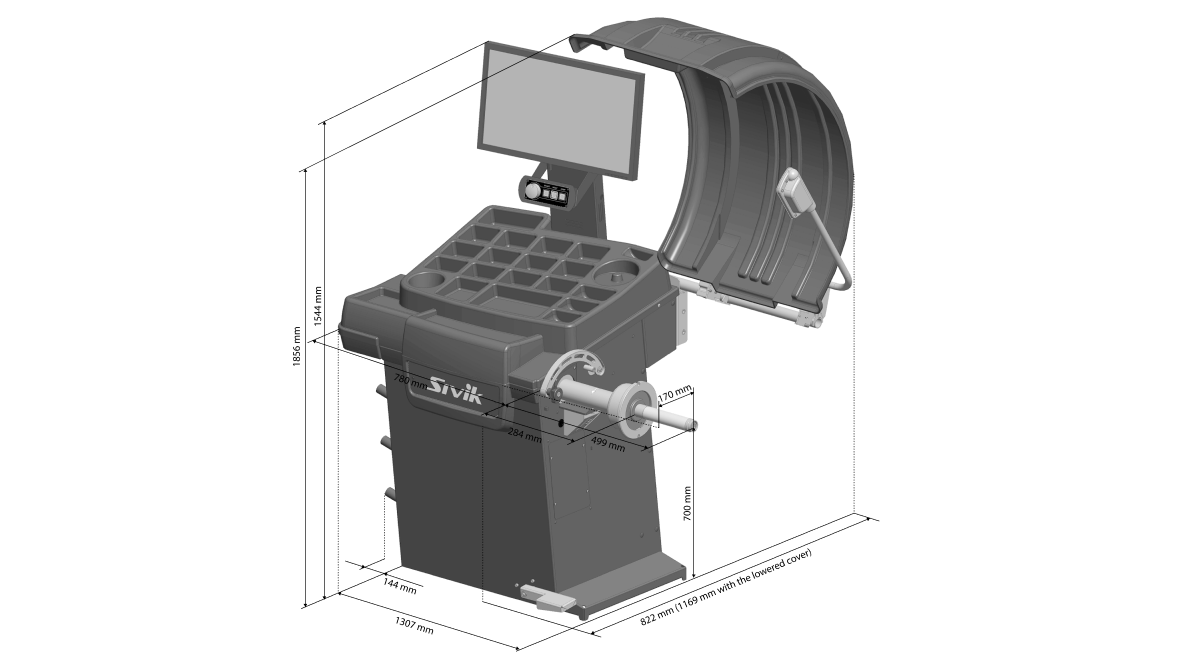

The machine shaft is placed as close as possible to the operator. Large shaft reach has been maintained - 284 mm for comfortable service even for the largest and widest wheels

The space saving cover design provides opportunity to put the machine close to the wall

Extended worktable with more storage cells for weights, cones, quick locking nut and other tools

The space saving cover design provides opportunity to put the machine close to the wall

Extended worktable with more storage cells for weights, cones, quick locking nut and other tools

THE MACHINE IS PROTECTED FROM POWER SURGE

PowerGuard technology reliably protects machine electronics from damage during power surges

TIRE POSITIONING FUNCTION

If the imbalance value is large, a tire positioning function can reduce the mass of the installed weights. It can be The optimization procedure under the machine guidance is faster and more accurate than manual one.

During a long (durational) optimization on the machine, it is possible to balance other wheels by switching to another operator.

During a long (durational) optimization on the machine, it is possible to balance other wheels by switching to another operator.

WIDTH MEASURING SONIC SENSOR

The machine automatically enters the rim width. The sonic sensor instantly reads the width when the cover is lowered. The sonic sensor use increases the speed of steel wheels balancing.

Max. wheel weight

70

Rim diameter setting range

28

Rim width setting range

20

Measurement uncertainty

1

Machine weight

152

Display

Touch-screen

Rim diameter range

900

Overall dimensions

1450х1140х1860

KS-227 SIVIK ARMOR

Standart

STANDARD balance cone set SIVIK ARMOR

Standart

Weight pliers

Standart

Message sent successfully

Our website uses cookies (files with information on previous visits to this website) to improve your browsing experience and show personalized content. By choosing “I Accept”, you consent to personal data processing according to Privacy policy published on https://sivik.net/