/div>

- Main

- -

- Catalog

- -

- Wheel balancing equipment

- -

- SPUTNIK LUXE

SPUTNIK LUXE 216

• SPUTNIK LUXE is an improved basic Sivik wheel balancer with boosted productivity and time-proven rugged design.

• Easy-to-operate, simple and reliable

• Accurate direct rim measurement function increases wheel service speed

FEATURES AND FUNCTIONAL COMPOMENT:

Direct3D – accurate direct alloy rim measurement

NoiseDown - vibration decreasing and electricity saving

PowerGuard - power surge protection

Split – aesthetic tape weight installation

Quick weight installation

Wheel cover or button triggered imbalance measurement start

Automatic wheel braking

Serviced wheel counter

Three user profiles

Adaptor imbalance compensation

Diameter and distance measuring electronic gauge arm

High- precision spindle block (40 mm shaft diameter)

• Easy-to-operate, simple and reliable

• Accurate direct rim measurement function increases wheel service speed

FEATURES AND FUNCTIONAL COMPOMENT:

Direct3D – accurate direct alloy rim measurement

NoiseDown - vibration decreasing and electricity saving

PowerGuard - power surge protection

Split – aesthetic tape weight installation

Quick weight installation

Wheel cover or button triggered imbalance measurement start

Automatic wheel braking

Serviced wheel counter

Three user profiles

Adaptor imbalance compensation

Diameter and distance measuring electronic gauge arm

High- precision spindle block (40 mm shaft diameter)

Add to comparison

AUTOMATIC DISTANCE AND DIAMETER ENTRY BY THE GAUGE ARM

STELLAR (P) is equipped with the diameter and distance measuring electronic gauge arm which provides high speed operation and eliminates errors

CONVENIENT IN WORK

New enlarged control panel with user-friendly menu

Special cover design provides easy access into the wheel.

Indicators visually display weights installation spots.

The control panel provides quick access to key functions.

Special cover design provides easy access into the wheel.

Indicators visually display weights installation spots.

The control panel provides quick access to key functions.

EFFICIENT IN ALLOY RIMS SERVICE

The Direct3D direct measurement of weight installation planes function takes into account the actual alloy rim shape and accurately calculates the weight. To enter the size, bring the gauge arm to the weight installation place.

Due to SmartSet technology, the machine evaluates the mass of the weight and chooses the best installation method: fast "6 o'clock" or precise with the gauge arm

The machine automatically turns the wheel to the weight installation place and holds it due to the S-Drive technology.

Wheel balancing in one cycle.

Split and set the weight behind the spokes using the Split function

Due to SmartSet technology, the machine evaluates the mass of the weight and chooses the best installation method: fast "6 o'clock" or precise with the gauge arm

The machine automatically turns the wheel to the weight installation place and holds it due to the S-Drive technology.

Wheel balancing in one cycle.

Split and set the weight behind the spokes using the Split function

HIGH QUALITY OF BALANCING (QUALITY WHEEL CENTERING)

The wheel is automatically pressed against the cup on the electromechanical shaft. There is an accurate wheel centering on the cone.

High- precision spindle assembly provides high quality balancing. Main balancing parts are manufactured with the precision of ±0.007 mm (shaft, threaded jaws, spindle).

40 mm shaft diameter allows the use of accessories from European manufacturers.

High- precision spindle assembly provides high quality balancing. Main balancing parts are manufactured with the precision of ±0.007 mm (shaft, threaded jaws, spindle).

40 mm shaft diameter allows the use of accessories from European manufacturers.

NOISEDOWN TECHNOLOGY INCREASES MEASUREMENT ACCURACY

Reduces noise and vibration generated by the electric motor

Saves energy

Saves energy

QUICK IMBALANCE MEASUREMENT START

Start imbalance measurement by pressing a button or by simply lowering the cover – saves time.

THE MACHINE IS PROTECTED FROM POWER SURGE

PowerGuard technology reliably protects machine electronics from damage during power surges

THE SCOPE OF WORK CONTROL

To account for the number of balanced wheels, the machine has a built-in automatic indelible counter that allows to control the amount of work performed.

THIS MACHINE ALLOWS TO SERVICE THE WIDE RANGE OF VEHICLES

For balancing wheels with rim diameter up to 26"

Allows to service passenger cars wheels, as well as light commercial vehicles wheels

Balancing motorcycle wheels with special adapters.

Allows to service passenger cars wheels, as well as light commercial vehicles wheels

Balancing motorcycle wheels with special adapters.

WEIGHT INSTALLATION WAYS

The weight can be set at 12 o'clock, at 6 o'clock, and also by the gauge arm.

Weight installation by the gauge arm is more accurate. The operator fixes the weight in the clamp, draws it out until the beep and presses the weight against the rim.

Weight installation by the gauge arm is more accurate. The operator fixes the weight in the clamp, draws it out until the beep and presses the weight against the rim.

Maximum wheel weight, kg

65

Maximum rim diameter, inch

26

Maximum rim width, inch

20

Minimum wheel diameter, mm

800

Accuracy, g

1

Shaft diameter, mm

40

Display

LED (21 mm)

Network voltage, V

220

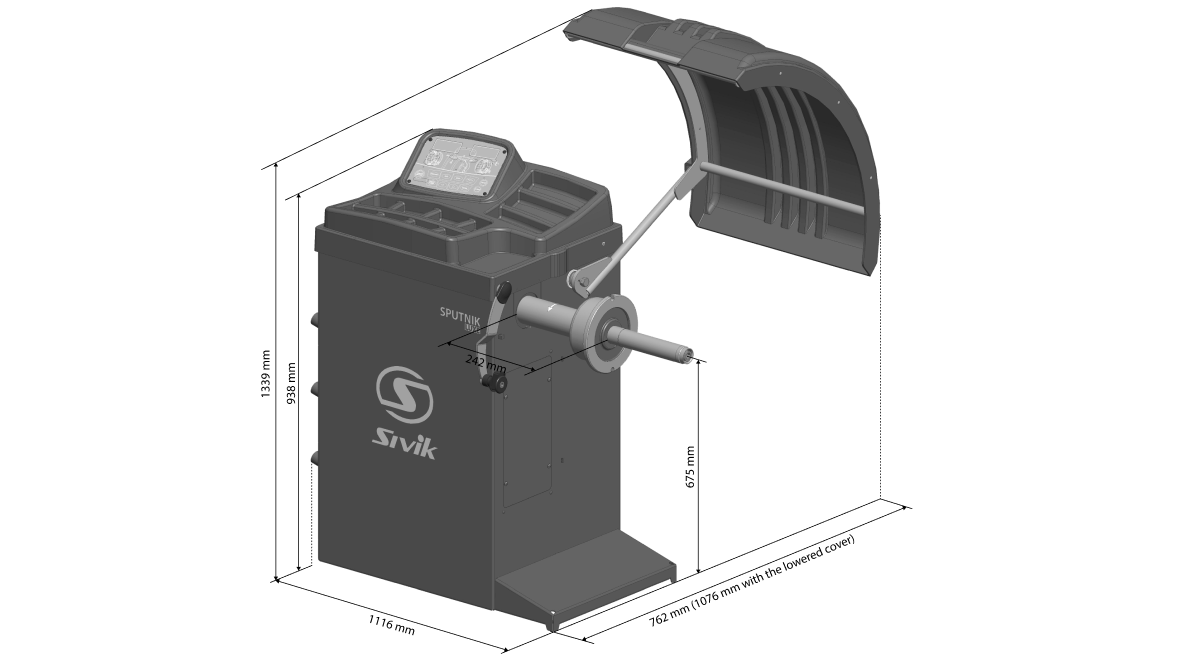

Overall dimensions, mm

1150x905x1245

Package overall dimensions, mm

1000x640x1080

Net weight, kg

78

Gross weight, kg

100

Colour

Blue/red

Calipers

Standart

Wheel width measurement calipers.

KS-227 SIVIK ARMOR

Standart

STANDARD balance cone set SIVIK ARMOR

Standart

Weight pliers

Standart

Message sent successfully

Our website uses cookies (files with information on previous visits to this website) to improve your browsing experience and show personalized content. By choosing “I Accept”, you consent to personal data processing according to Privacy policy published on https://sivik.net/